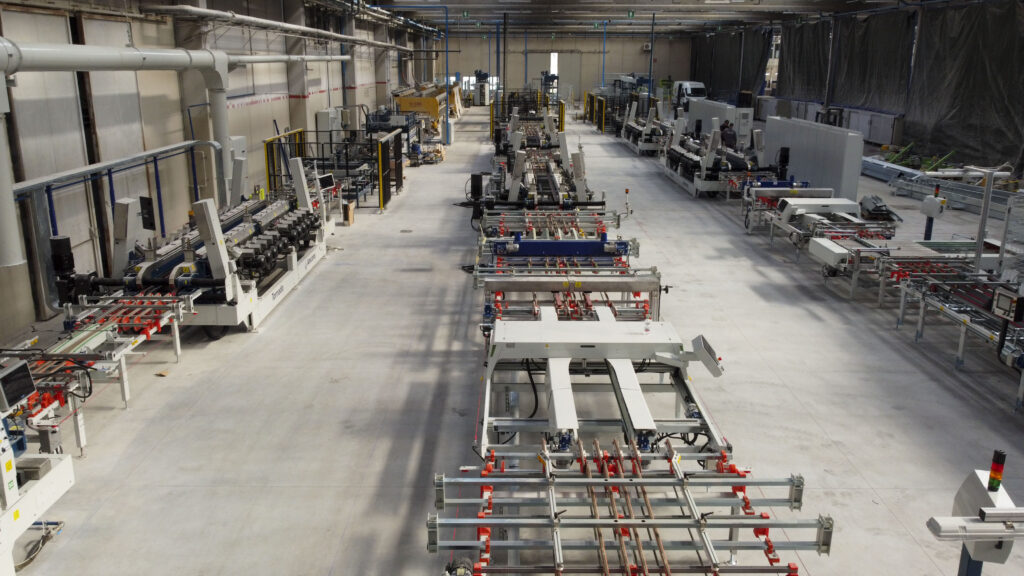

A new arrival at the Toano site, TORNADO by Ancora provides latest generation technology for end-of-line processes

Panariagroup chooses Gruppo B&T Group as a key partner for the procurement of increasingly innovative technologies. More specifically, the ceramic group has recently purchased and installed three complete TORNADO squaring lines for its plant in Toano, in the province of Reggio Emilia.

Manufactured by Ancora, a Gruppo B&T company and leader in finishing technologies, these three lines consist of the TORNADO squaring machine and the ARKO, KROS, and COMBICUT engraving and splitting machines. The line is already up and running at full capacity, after the installation work was completed at faster than usual speeds in order to meet the customer’s needs. Three latest generation systems for sizes of up to 120×120 cm and 90×180 cm, with thicknesses up to 20 mm.

As they are fully automated, a single operator can run up to three lines at the same time; their constant reliability and great ease of management, meanwhile, make them an accessible and easy-to-use technology. The new highly intuitive and user friendly EASY-STEP software guarantees continuous updating of the machine-production status and guides the operator through the machine’s management step by step.

Built with the highest quality materials and fully automated, TORNADO is the new dry squaring machine for large productions designed for the ceramics industry. An extremely sturdy and stable machine, its placement at the kiln outfeed ensures a more efficient squaring process resulting in significant lower logistics and management costs and also maximised productivity (reaching numbers in the order of 20,000 m2 /day). With the new laser system, the grinding process can be measured and controlled in real time, with automatic intervention in the event of errors, which guarantees continuous accurate grinding over time. All of this, of course, has advantages for the environment, as TORNADO brings with it lower energy consumption, in addition to lower operating costs and simpler and cheaper maintenance.

Innovative technologies which both ensure maximum productivity and quality and enable Panariagroup to process all its products without the need for external assistance, thereby cutting down costs even further.

The identity of Panariagroup has always been rooted in innovation, the latest technology, and dedication to efficiency improvement. The group has always invested in its industrial sites, to maintain its ranking as one of small group of industry leaders. This new acquisition confirms the company’s innovation strategy.

“We are very happy – stated Fabio Tarozzi, chairman and CEO of Gruppo B&T – to be working once again with Panariagroup, on a project that, for us, is the ultimate end-of-line technology. Panariagroup has always and continues to demonstrate to the world its leadership in the production and distribution of ceramic tiles for floors and walls. We are proud to be alongside the group on its journey, with machinery designed specifically to offer our customers the best”.