Last April LB signed an agreement with SAXA GRES, the most important producer of floor and wall materials located outside the Sassuolo district, for the supply of a plant consisting of 3 complete lines for the body preparation to make “sampietrini” in porcelain material. This product is a very similar but more economical and sustainable version of the classic basalt cube, which has become an import product from the Asian markets.

The above project will let SAXA GRES and its unique products play a more and more important role in the ceramic “Made in Italy”. The main features of this challenge are: innovation, sustainability, aesthetical know-how and high range materials.

The plant will start operating in early 2020 and will allow a total production of 45 tons / hour.

The savings guaranteed with the use of LB technology compared to the traditional wet processes are the following:

gas: 68,2 %

water: 69,7 %

additives: 95%

The plant is equipped with the new LB 4.0 software systems to control the production processes and to ensure the maximum possible efficiency.

The supply also includes a maintenance and preventive program with the sale, management and installation of spare parts.

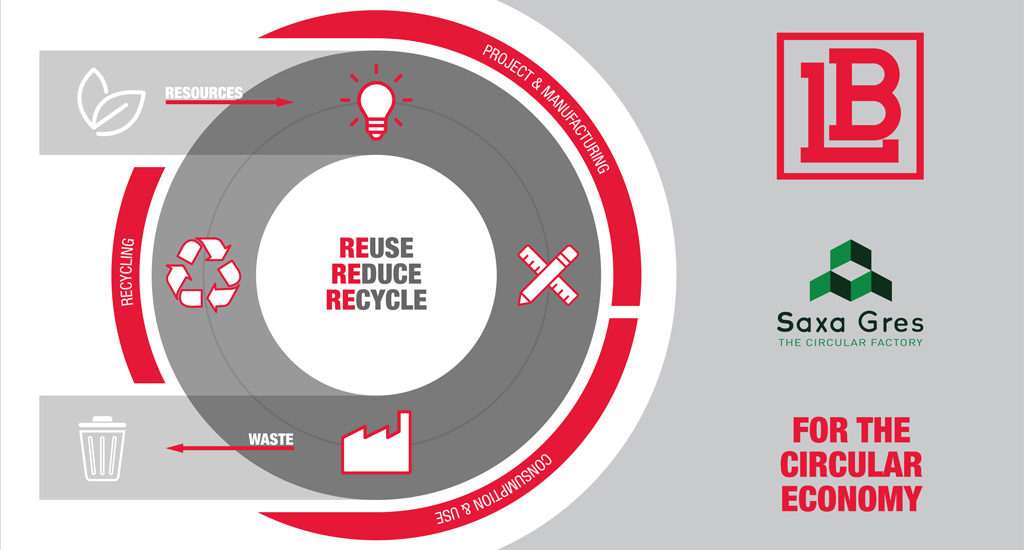

The success of this challenge was made possible by the activation of the circular economy: there is no more waste, only material or energy to be reused, with innovative patents and new economical processes.

The raw material, treated with LB technology, in this case becomes a source of savings / profit because the company of Roccasecca (Frosinone) gets a return using a type of inert ashes, an incinerator processing waste which is currently very expensive to dispose of.

In fact, the SAXA GRES outdoor material will be composed for approximately for one third of these recycled materials.

With this innovation, you can prevent the raw materials exhaustion and reactivate technological skills and experiences now getting lost.

The circular and sustainable project of SAXA GRES wants to enhance mainly human capital.

With the reopening of the Roccasecca plant, the company has guaranteed a hundred new jobs. An operation that is not easy in times of crisis like the ones we are experiencing and for a particularly suffering areas like the one of Roccasecca.