Tecnosint Group Srl is a company that looks to the future, combining its twenty-year experience in the business of polishing with important investments focus on research thereby allowing it to operate using the most advanced technologies and guaranteeing innovative products of the highest quality.

Tecnosint Group Srl manufactures diamond abrasives (resin bonded and sintered) as well as brushes for polishing of all materials (natural, engineered stones and ceramic). Daily, it develops solutions to all kinds of problems regarding the surfaces processing.

Through the expertise of its skilled staff together with a constant contact with its customers and manufacturers of machines used in the stone polishing industry, Tecnosint Group has created innovative, flexible and customised technical solutions capable of guaranteeing the best results and the maximum productivity. The company’s professionalism and passion with which it is run are essential qualities and determine the huge worldwide success of the Tecnosint Group brand, representing the highest Made in Italy quality.

Tecnosint Group has developed a new production technology “by sinter” that, combined with the usage of resin with superior mechanics properties, allows a homogeneous distribution of the powders all through the abrasive. The main advantages connected to the usage of the Orion abrasives are the complete absence of big holes inside the abrasives, the constant and very high cutting capacity, that remains the same though all the life of the abrasives, the superior life and reduction of the polishing costs The Orion abrasives by Tecnosint Group, originally available only in the “full” design, now are available also in the 10,17 and 21 sectors abrasives, from grit 40 to 800.

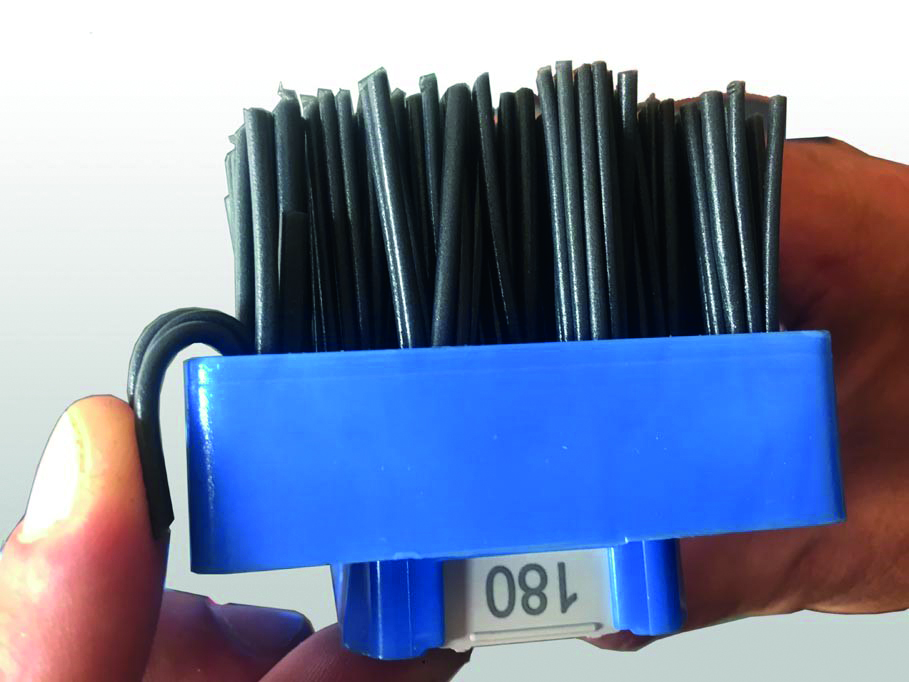

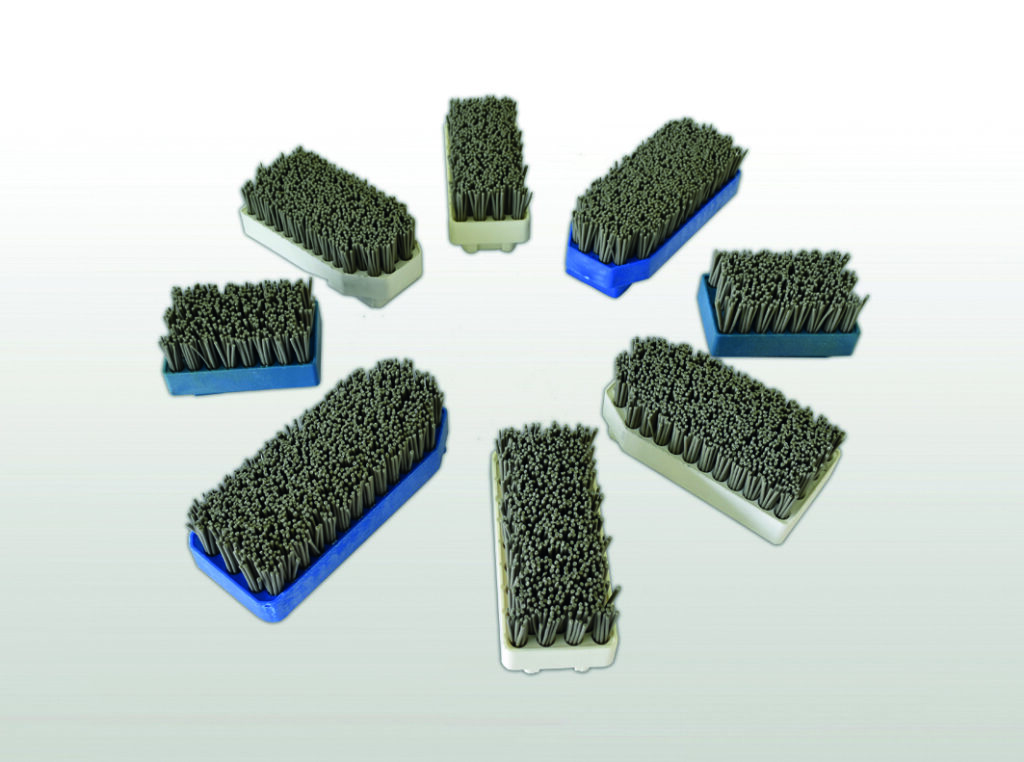

In the market of the rubber abrasive used to achieve matte/honed surfaces, Tecnosint Group confirms his predisposition to create innovative products, releasing a new generation of brushes with rubber wire instead of the standard peg (“Pioli”) rubber abrasives. EASYFLEX brushes, whose purpose is to dull and homogenize the matte/honed surfaces, gives numerous advantages by its flexibility due to its thin wire diameter and to the special rubber polymer utilized. Due to these factors, Easyflex rubber brushes can reach all the depressions in the textured surfaces and they can give the most homogeneous results on the flat matte surfaces.